Our Approach to Asset Safety and Integrity

For Equitrans, the functionality and safety of our assets, such as our pipelines, is crucial to our business values and success. The primary goal of our pipeline safety practices is to protect our employees, contractors, and the local communities where we live and operate. Our pipelines are operated, maintained, and repaired in accordance with current U.S. Department of Transportation (DOT) regulations and industry standards for safe pipeline operations, including the American Society of Mechanical Engineers’ Gas Transmission and Distribution Piping Systems Standard and the American Petroleum Institute’s Recommended Practices 80 for Onshore Gas Gathering Lines. We adhere to federal U.S. DOT gas transmission pipeline integrity regulations (49 Code of Federal Regulations (CFR) 192, subpart O) and regularly complete public safety assessments, such as pipeline encroachment and leak surveys, confirmation excavations, and materials testing to ensure asset integrity on both high-pressure gathering and transmission assets. As we strive to exceed regulations, these supplemental assessments, while not always required by federal or state government agencies on non-jurisdictional assets, are an important part of our safety culture.

Additionally, the Pipeline and Hazardous Materials Safety Administration (PHMSA) is an operating administration with the U.S. DOT that develops and enforces requirements for the pipeline transportation system. In 2020, Congress enacted the 2020 Protecting our Infrastructure of Pipelines and Enhancing Safety (PIPES) Act. Section 114 of the 2020 PIPES Act is often referred to as the “methane mandate” and requires pipeline operators to update policies, plans, and procedures to include mechanisms and work procedures that document how methane is being mitigated across the pipeline system — an industrywide requirement that goes above and beyond the rules set forth by traditional environmental regulators. Equitrans complied with the methane mandate by updating our Operations and Maintenance Plan (O&M Plan) to include processes, procedures, and methods that we currently utilize to eliminate leaks and minimize methane emissions. As with other industry operators, we were audited by PHMSA in 2022 to gauge our adoption. Equitrans is pleased to report there were no findings that resulted from the audit.

Equitrans is committed to working with oversight agencies to embed our environmentally conscious practices into pipeline safety documentation. While there was no additional funding needed to comply with the methane mandate, we proactively invested approximately $2.5 million in pipeline safety initiatives and $1.6 million in corrosion prevention activities in 2022. In addition to traditional in-line inspection and corrosion activities, the budget accounts for an accelerated well-logging schedule, risk management of storage wells, additional PHMSA audits and inspections, and well remediation costs.

With our continued commitment to protect our workers and local communities, we strive to manage the risk and probability of a serious asset-related incident. With a goal to mitigate risks, we developed a detailed set of internal safety procedures specific to pipeline design, construction, operation, and maintenance. Through these pipeline lifecycle phases, we proactively integrate preventive measures to enhance the safety of our employees, contractors, and community members.

Pipeline Lifecycle Phases

Design

During a pipeline’s design phase, we take every opportunity to embed safety practices. This process starts with extensively evaluating applicable federal, state, and local regulations and then adapting the design components and procedures to meet those regulations. When designing, we also ensure the pipeline and its supporting infrastructure are consistent with industry standards and best practices for asset safety, efficiency, and reliability.

Equitrans also incorporates external factors in the design phase, as the pipeline itself is not our sole focus. We proactively optimize a pipeline’s route to avoid, wherever possible, sensitive environmental and cultural areas, as well as unforeseen impacts to local communities.

Construction

Throughout a pipeline’s construction, it is critical that we make every effort to confirm the pipeline is properly constructed and installed in accordance with our high compliance standards. To do this, we inspect all activities both during construction and upon completion to verify the safety and integrity of the pipeline and to ensure proper installation procedures were utilized. One crucial aspect of this inspection process is the examination of welds to confirm their integrity before the pipeline is placed into service.

Lastly, before a pipeline is approved and placed into service, we extensively assess the asset to confirm its fitness for service. We test the pipeline by using regulatorily accepted integrity checks prior to the introduction of gas, including hydrostatic pressure tests and pipe geometry inspections (e.g., pigging) to check for dents and ovality. When applicable, cathodic protection and voltage gradient surveys are also utilized to confirm the effectiveness of corrosion protection systems.

Operations

Equitrans’ priority is maintaining a pipeline's safety and functionality throughout its entire operation. To ensure this, we monitor pipelines and supporting assets during operation to detect any shifting or potential disturbances. Employees in our state-of-the-art Gas Control Center control, monitor, and analyze the natural gas flowing through our pipelines 24 hours a day, seven days a week — enabling us to quickly identify and respond to any potential issues that may arise and resolve those issues as quickly and as safely as possible.

Equitrans mitigates the risk of pipeline corrosion through industry-standard cathodic protection system maintenance, which applies impressed electrical current to the pipeline to inhibit corrosion. This is accomplished by installing sacrificial anodes and ground beds along the pipeline route, which are designed to corrode at known rates, in lieu of corroding the pipeline. We also deploy other corrosion prevention strategies, including routine sampling to quickly identify if corrosion is occurring, as well as flow controls to limit excessive gas velocities within the pipeline, which can often erode the pipe.

Our landslide management program outlines landslide inspection frequency and response time following weather-related events. These guidelines help to ensure that pipeline integrity concerns are discovered and addressed in a timely manner. In addition, Equitrans’ engineering team monitors rainfall data and freeze/thaw cycles in our operating areas to ensure adequate pipeline inspections are conducted to determine the impact of known landslides on our pipeline systems. Semi-annually, Equitrans conducts light detection and ranging (LiDAR) data collection on the majority of our pipeline systems to detect any new slides that may have occurred on the pipeline rights-of-way (ROWs). Additionally, for any pipeline suspected to have been subject to movement, we perform a strain analysis and develop a monitoring plan, which may include baseline surveys, staking, and subsequent drone monitoring to track any pipe shifting.

Another important strategy we leverage to evaluate pipeline safety is maintenance of the pipeline ROW. Along with routine, on-the-ground safety inspections, it is important to keep the ROW open and clear to easily conduct aerial safety patrols using helicopters and drones. When our Gas Control Center or inspections teams identify a safety or maintenance concern, we act swiftly to remediate it. Our internal operations and maintenance program teams work together to promptly mitigate and resolve any issues to ensure the integrity and longevity of our operational assets.

Integrity Management

The preparation for and mitigation of a potential pipeline issue are vital to ensuring safe operations. Equitrans’ compliance, corrosion, and technical training teams within the pipeline integrity department, as well as the field operations department, share the responsibility of managing pipeline integrity. These teams evaluate and maintain standard operating policies, procedures, and pipeline construction records. The pipeline integrity and field operations departments oversee the operator qualification program and other relevant trainings for employees and contractors. Equitrans’ pipeline integrity trainings empower workers to identify and mitigate potential integrity risks.

Additionally, the teams utilize industry-accepted formulas on pipeline characteristics to identify high-consequence areas that have the potential to affect local populations, buildings, and land near the pipeline route. The teams also use a Geographic Information System (GIS)-based risk model to implement strategies to improve the health of the system. Equitrans’ pipeline integrity department also evaluates corrosion, participates in government audits, performs internal audits, and reviews pressure tests when applicable.

As an example of actions taken to mitigate integrity concerns, Equitrans has remediated all known bare steel transmission pipelines with coated steel pipelines to increase integrity and reduce incident risks. Coated steel has a protective outer layer which makes the pipe more durable, while also requiring less maintenance and increasing cost effectiveness over the long term.

Pipeline Security

Ensuring the safety and integrity of our pipelines also requires that we stay informed of security-related risks and act diligently to reduce these risks and any potential dangers. We safeguard our assets through meticulous security planning and on-site strategies including fences, building locks, electronic monitoring, and continuous surveillance. For more information, see the Security and Cybersecurity section of this report.

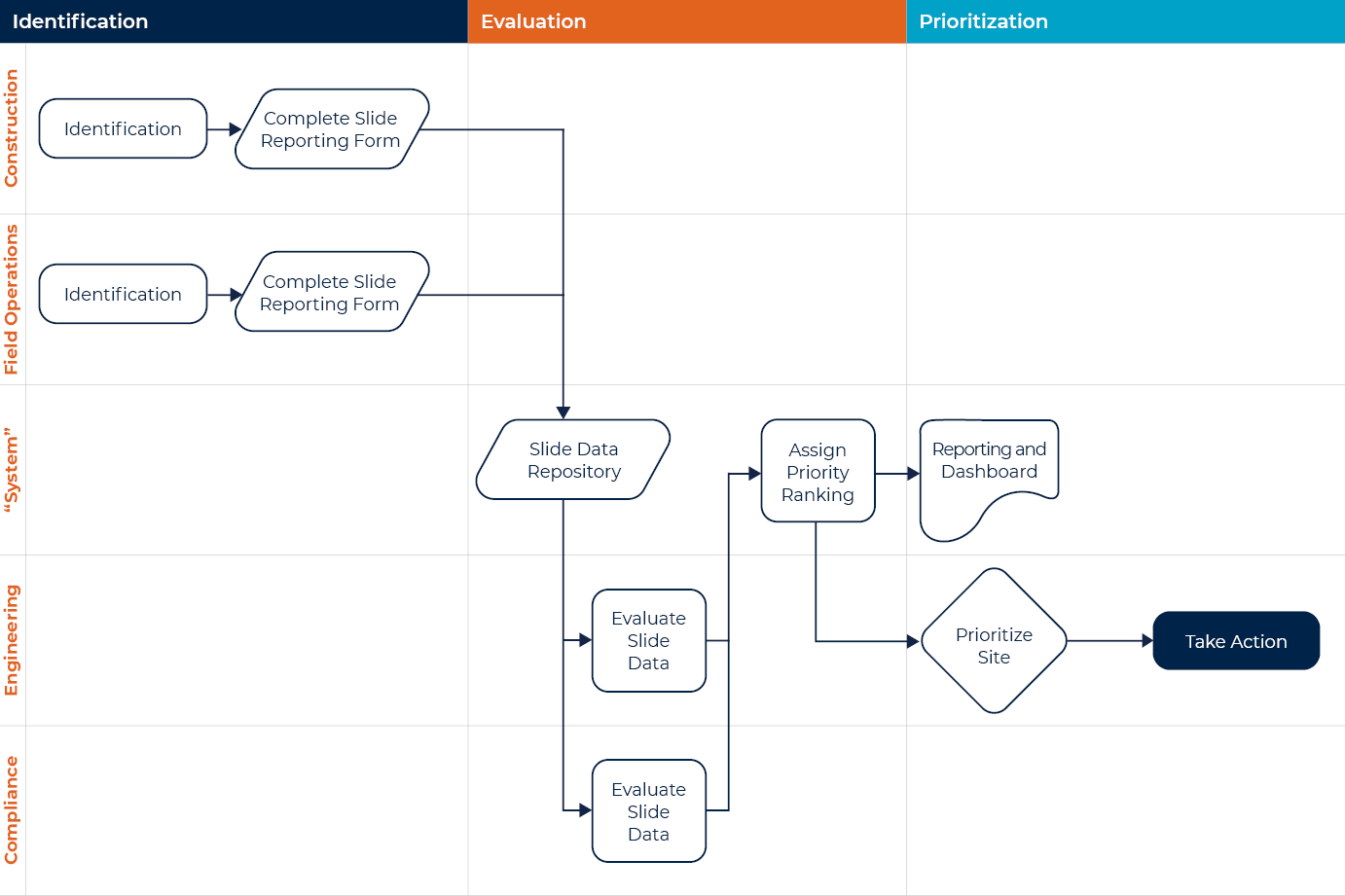

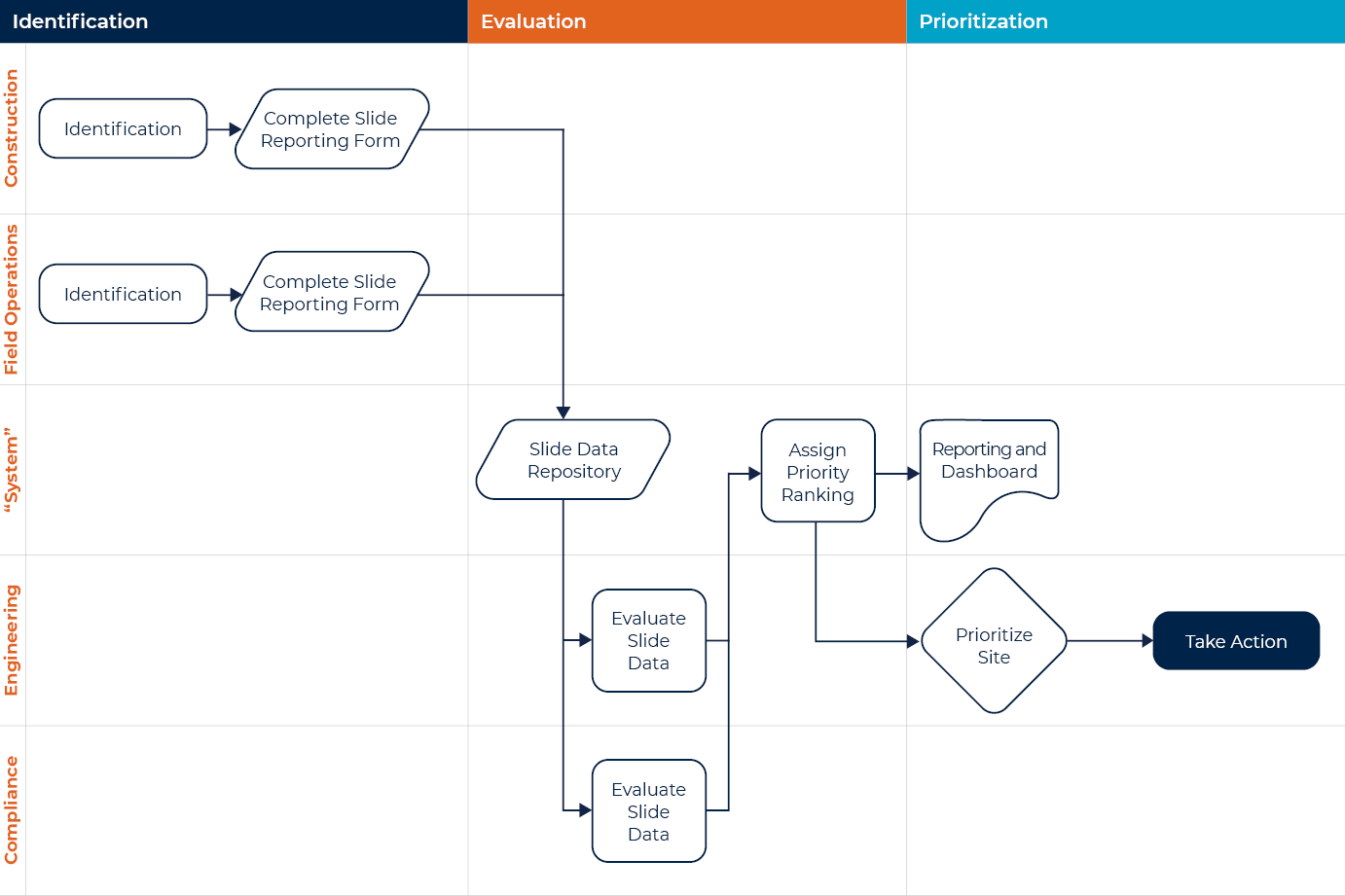

Slip Prevention Plan

Slips occur when land shifts from a stable to an unstable condition, which could potentially affect the integrity of our pipe. An unstable condition is caused by environmental disturbances, such as soil erosion or excessive rainfall or snowmelt, which loosen the soil either underground or on top of our pipelines. Prior to commencing construction, Equitrans analyzes the proposed pipeline site with ground and aerial surveys, historical landslide mapping, and soil maps to identify landslide-prone soils. These measures help minimize the risk of slippage and environment disturbance.

Once in the operational phase, we utilize ground surveys, drones, GIS, in-line strain identification, and data analysis to monitor soil movement and identify pipeline slips. Equitrans’ engineering team also identifies areas where slip risks may occur along our pipelines and notifies our compliance and operations teams of the risk severity. If a site is determined to have a high risk of slippage, our engineering team will conduct on-site surveys and, when necessary, implement measures to ensure our pipelines remain stable. In addition to directly monitoring areas of concern, our compliance team conducts aerial surveys bi-annually.

Storage Well Safety and Integrity

To fulfill regulatory obligations, Equitrans conducts annual audits and inspections required by PHMSA and state pipeline safety agencies. In recent years, PHMSA has conducted focused audits related to the integrity management programs for underground natural gas storage, due to prior industry incidents. These intense and detailed audits emphasize both the public safety component and the potential environmental impact of methane releases. Under PHMSA’s direction, Equitrans conducted numerous storage audits to gauge the strength of our Storage Integrity Management Plan (SIMP) and its adherence to the federally published code. The integrity team addressed all the action items to improve the SIMP, and instituted the following enhancements to our storage operations:

- Updated the frequency of well surveillance logging from every 15 years to every seven years to mitigate incident risks

- Utilized Remote Terminal Units on storage wells to allow 24-hour monitoring through our Gas Control Center

- Developed and implemented storage-specific procedures to standardize storage maintenance and operations activities

- Provided dedicated personnel trained specifically for storage operations

Rager Mountain Storage Facility Incident

Operating as a storage pool since 1971, Equitrans’ Rager Mountain facility is a FERC-certificated and -regulated storage field located in Jackson Township, a remote area of Cambria County, PA. The Rager storage field has a total capacity of approximately 11,600 MMcf of natural gas, making it Equitrans’ largest-capacity storage field. The facility includes two observation wells, along with 10 injection and withdrawal wells that are connected by pipelines to the Allegheny Valley Connector interstate pipeline system via the Laurel Ridge and Rager Mountain facilities.

On November 6, 2022, an incident occurred at our Rager Mountain facility that involved natural gas escaping from a 1 5/8″ vent on a single storage well (well 2244), which was working as designed to relieve pressure from the casing. There were no injuries reported, no mandatory evacuations of nearby property owners, and no immediate public safety concerns. As a result of the incident, all physical flows of natural gas in and out of the Rager Mountain Storage facility were temporarily suspended. Equitrans worked with a specialty well services company to address and resolve the venting, and the flow of gas was stopped on November 19, 2022.

Immediately following the plugging of storage well 2244, post-incident response activities were initiated, including a complete environmental assessment of the facility and surrounding area, as well as a standard five-day shut-in test on all storage wells at Rager Mountain to estimate the total change in inventory at the Rager storage reservoir. Based on a comparison to the standard shut-in test performed in April 2022, the results of the inventory verification test indicated the Rager storage inventory was reduced by an estimate of approximately 1.29 Bcf. Equitrans continues to evaluate whether and to what extent all of the inventory loss was due to venting or whether some was due to potential migration.

In coordination with PHMSA an independent, full root cause investigation is underway and is expected to be complete in summer 2023. In addition to the root cause investigation, Equitrans is collectively evaluating all wells at the Rager storage field, including performing wireline testing and other additional tests to ensure the integrity of the wells prior to resuming injection activities.

More broadly, Equitrans is evaluating its policies and procedures in light of regulatory requirements and best practices; conducting a third-party audit of all Equitrans storage field operations; and, based on historical data, performing additional wireline testing on wells throughout the Company’s storage field operations.

As part of ongoing post-incident response activities, Equitrans will continue to inform the respective state and federal agencies of its activities and findings, including as it works to return the field to injection operations. Additional information regarding the Rager Mountain incident can be found in the GHG Emissions and Climate Change and the Public Safety and Emergency Response sections of this report.

Managing Releases

Our mitigation procedures and measurements are designed to ensure safety in the event of a spill or leak related to one of our assets. If a leak is detected on an asset, we work diligently to detect the location of the leak, take immediate action to make repairs, and quickly remediate any damage. Our teams conduct regular inspections of our pipelines to ensure their integrity. In 2022, approximately 12% of our natural gas transmission pipelines were inspected per 49 CFR 192 Subpart O requirements for High Consequence Areas (HCA). Furthermore, Equitrans routinely inspects additional miles of non-jurisdictional pipelines, which are not regulated by the DOT. If any areas of concern are identified during inspections, we take immediate action to maintain the integrity of the asset and ensure regulatory compliance.

Equitrans regularly evaluates our processes and strives to limit operational leaks and releases. In the spirit of continuous improvement, we learn from past projects to better mitigate the risk of future leaks. We track all leaks and releases and gather data for each of our compressor stations, storage wells, and pipelines. Our operations team periodically reviews our data to identify any trends or long-term concerns that may require technical solutions from our engineering team and also works to implement proactive solutions for mitigating or avoiding future impacts. This process involves a proactive and regimented aerial and foot patrol program following U.S. DOT guidelines.

As an additional means of responsibility and transparency, our Notices of Violation (NOV) Tracker provides public disclosure of Equitrans’ formal notices of non-compliance and violations.

When an incident occurs, Equitrans properly reports all releases in line with state and federal regulations. The following table summarizes our reported natural gas incidents for 2019-2022. The significant increase in year-over-year data for our 2022 reportable releases is primarily related to the Rager Mountain Storage facility incident, described in detail above in the ‘Storage Well Safety and Integrity’ sub-section.

|

Natural Gas Incidents1

|

2019

|

2020

|

2021

|

20222 |

|

Number of Reportable Incidents3

|

2

|

0

|

0

|

2 |

|

Volume of Reportable Releases (MCF)3

|

19,900

|

0

|

0

|

1,300,000 |

|

Percentage Reportable Incidents That Were Significant4

|

0%

|

0%

|

0%

|

100% |

Managing Compliance

In alignment with our commitment to meet or exceed compliance regulations, it is our goal to always be transparent when interacting with local, state, and federal authorities. We routinely track and evaluate all emerging and changing regulations and permit requirements that may impact Equitrans’ business and operations. Where appropriate, we actively submit comments based on our evaluations of proposed regulations, either as a Company or through the industry trade groups of which we are members.

Equitrans believes it is equally important to be transparent when we do not live up to our expectations and, especially so, when we fall short of federal, state, or local requirements for asset safety and integrity and/or environmental compliance. We take our responsibility seriously and respond to all agency notifications, keeping record of our due diligence and maintaining our commitment to compliance. As an additional means of responsibility and transparency, we implemented a Notices of Violation (NOV) Tracker to publicly disclose Equitrans’ formal notices of non-compliance and violations. The tracker, which is routinely updated and published on the Sustainability page of our website, summarizes our compliance data and acts as an accountability measure. Types of enforcement actions include NOVs, Notices of Amendment (NOAs), Notices of Proposed Safety Order, and warning letters from state utility commissions and PHMSA. Environmental NOV information can be found in the Environmental Compliance section of this report.

Equitrans routinely tracks and evaluates all emerging and changing regulations and permit requirements that may impact our business and operations.

It is important to note that all agency audits are not equal and can range in duration from a few days to several weeks — with operators potentially receiving multiple citations in a single audit, depending upon the type of deficiencies identified. Additionally, as newly implemented regulations continue to mature, it is not uncommon to receive citations of lesser severity (i.e., warning letters or NOAs). These types of enforcement are typically non-punitive in nature and are utilized by the agencies to create awareness and provide an opportunity for the operator to update policies, plans, and procedures to more accurately align with regulations.

As shown in the table below, there has been a steady increase in the number of scheduled audits, which has a direct correlation to the increase in enforcement actions. The post-audit interaction between agencies and operators is also changing. The process now includes formal documentation of written findings and improvement opportunities prior to the issuance of an enforcement action. Equitrans strives to achieve zero enforcement actions by any agency, but welcomes these opportunities for continuous improvement. As of the publishing of this report, the final enforcement actions, and any associated penalties, related to the Rager Mountain Storage facility incident have not concluded.

|

Asset Safety Actions1

|

2019

|

2020

|

2021

|

2022

|

|

Scheduled Agency Audits

|

4

|

9

|

18

|

12

|

|

Enforcement Actions

|

0

|

2

|

3

|

7

|

|

Penalties Paid Associated With Enforcement Actions

|

$0

|

$0

|

$0

|

$0

|

|

Total Monetary Losses From Legal Proceedings Associated With Federal Pipeline and Storage Regulations

|

$0

|

$0

|

$0 |

$0 |

Maintaining Asset Safety and Integrity

Equitrans utilizes a range of risk mitigation strategies as part of our asset management and operations. In addition to strict adherence to all federal regulations, we require that non-destructive testing (NDT), such as x-rays or ultrasonic, be performed on all pipeline welds to ensure they meet industry requirements for acceptability. On large projects, we hire NDT auditors as supplemental oversight for additional review and verification. Every welder performing work on our pipelines must hold an Equitrans Welder Certification to ensure their welding follows our procedures and best practices. Prior to being placed in-service, completed pipelines are hydrostatically tested significantly above the normal operating pressure to ensure the integrity of all components. Data logging software is utilized to record critical data points during testing, and this information is reviewed by our engineering team to verify that testing meets all specifications and requirements. Specific to our storage facilities, Equitrans has installed electronic, remote monitoring devices that enhance our real-time data gathering capabilities by sending data to our operational control systems every three to five minutes.

During 2022, Equitrans continued to evaluate and implement the requirements of PHMSA’s Mega Rule, which was designed to improve pipeline safety and better prepare emergency responders for incidents.

Importantly, our inspectors verify that our pipeline construction contractors have qualified workers who follow our Design and Construction Manual and other procedures. While many of our inspectors possess industry-recognized certifications for their crafts, Equitrans’ inspectors are required to complete in-house training on Equitrans’ specifications to ensure pipeline construction meets both Company and federal government standards. These training modules educate inspectors on Equitrans’ best practices and required procedures for pipeline inspections. In addition, inspectors are routinely audited in the field to ensure projects are being completed following Company and applicable regulatory requirements.

During 2022, Equitrans continued to evaluate the requirements of PHMSA’s Mega Rule and began to incorporate changes in inspections, along with other actions, to prepare for the additional provisions outlined in the Rule. Through three main elements, the Mega Rule was designed to improve pipeline safety and better prepare emergency responders for incidents by:

- Intensifying risk assessment and maximum allowable operating pressure (MAOP) requirements

- Expanding regulations to include gathering lines and other previously non-regulated lines

- Increasing reporting requirements and safety regulations

Equitrans’ initial actions included enhancing and updating the language of various plans and processes, such as SOPs, O&M plans, and job plans, to better align and comply with the requirements of the new regulation. Additionally, to comply with specific sections of the Mega Rule, namely the MAOP verification of grandfathered pipe, we undertook supplemental measures to perform investigative research of records and to obtain the metallurgical composition of pipe while conducting confirmation digs. At Equitrans, compliance is just a start, and, while many of our plans and programs were already closely aligned with the new provisions, we expect to implement further actions to comply with the Mega Rule during 2023.